TORONTO, Aug. 21, 2024 (GLOBE NEWSWIRE) -- Xanadu Mines Ltd (ASX: XAM, TSX: XAM) (Xanadu, XAM or the Company) is pleased to report an increase in the Mineral Resource Estimate (Resource, Mineral Resource Estimate or MRE) for its flagship copper-gold project at Kharmagtai, in the South Gobi region of Mongolia (Figure 1 andTable 1). The updated Resource increases contained copper metal by 14% or 463kt Cu and contained gold by 9% or 764k Oz Au and is largely driven by updating the resource reporting criteria to reflect pit-shells generated in the pre-feasibility study (PFS) in conjunction with re-estimation of the underlying models to include 7,300m of new drilling completed in six holes at White Hill and five diamond drill holes at Golden Eagle.

Highlights

- Significant increase in Kharmagtai Resource from 3.4Mt to3.8Mt Cu and from 8.5Moz to 9.3Moz Au contained metal, a 463Kt increase in contained copper (Cu) and 764Koz increase in contained gold (Au).

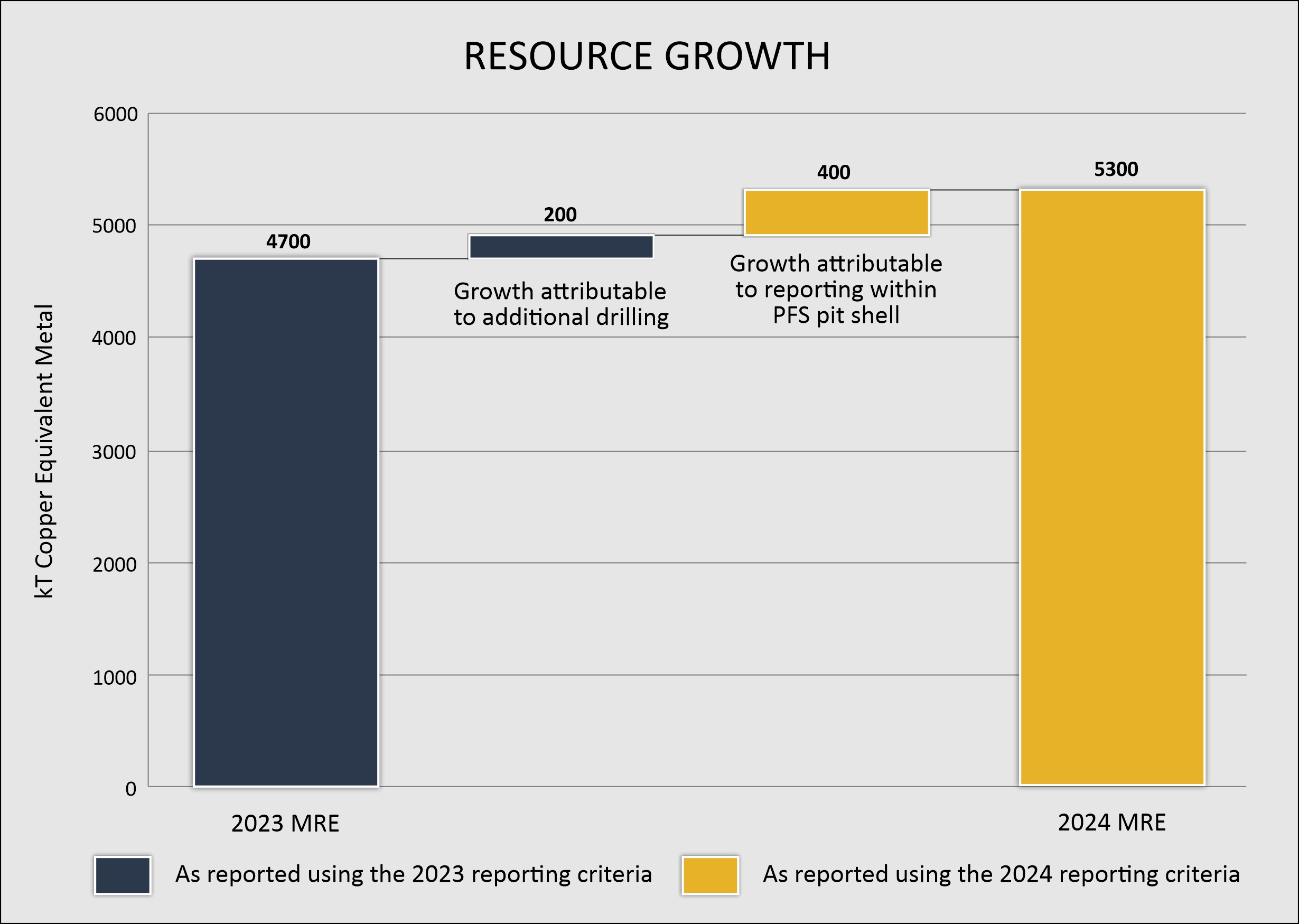

- A small increase of approximately 123kt of contained copper and 156koz of contained gold arose from an update of the underlying models to incorporate new drilling subsequent to the last MRE update (11 holes for approximately 7300m). The Competent Person also made some minor adjustments to classifications as part of this update.

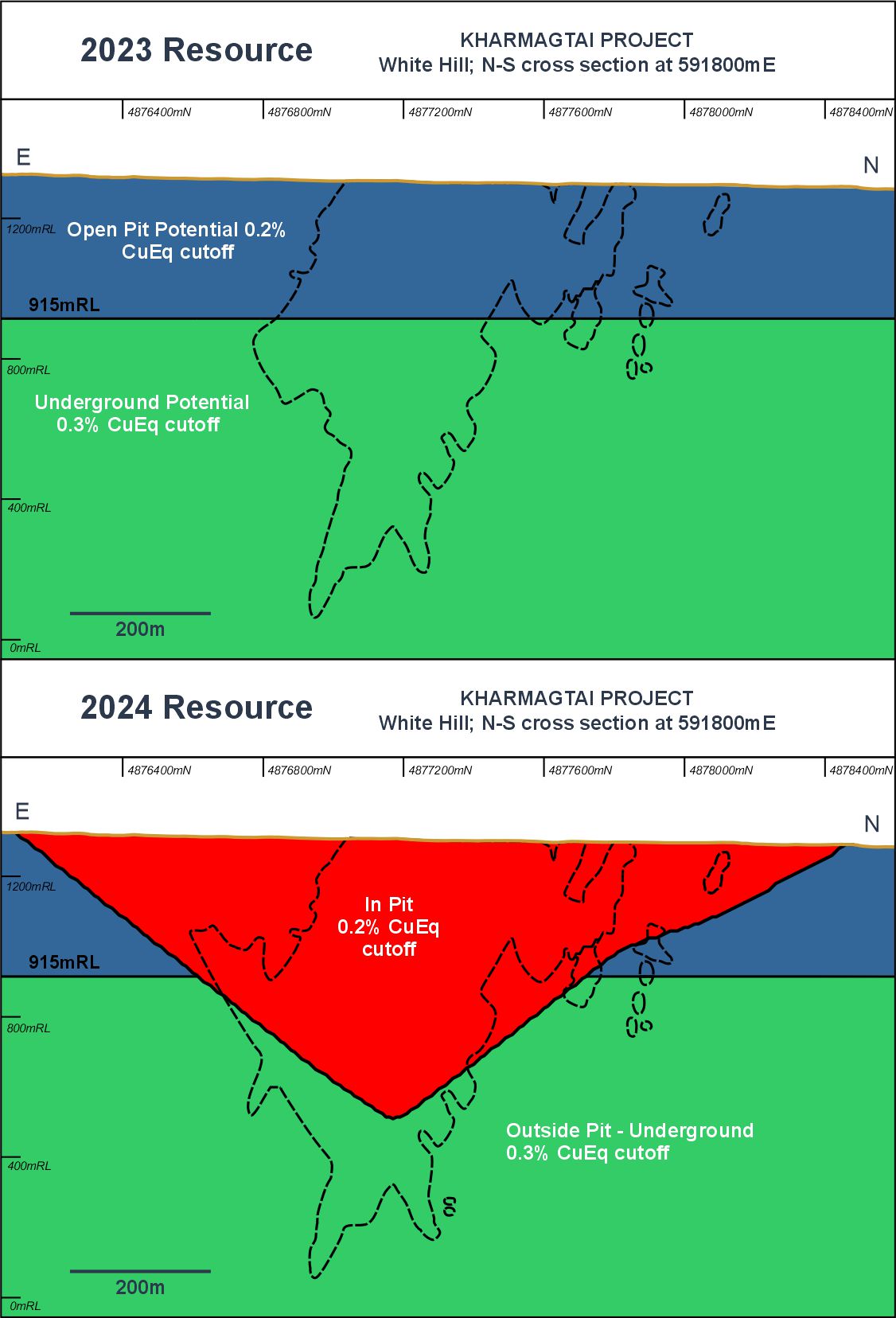

- The balance of the change was driven by reporting the Mineral Resource falling within the revenue factor 1.4 PFS pit optimisation shells to the notional open pit cut-off grade of 0.2% CuEq, with material falling outside those shells reported to the notional mass underground cut-off of 0.3% CuEq resulting a net increase of material being reported at the lower cut-off. The previous approach used subjectively derived flat relative levels to define potentially open pit resources from underground (refer Figure 3).

Xanadu’s Executive Chairman and Managing Director, Mr Colin Moorhead, said“This update reflects and is consistent with the final model informing The Kharmagtai PFS, which is on track for delivery in the current quarter. We are keeping all planned infrastructure outside of the revenue factor 1.4 pit-shells to ensure sufficient flexibility for the open pits to grow in the future. There is therefore a reasonable expectation that mineralisation falling within those pits may eventually be extracted by open pit mining and it is appropriate that this Mineral Resource is reported to cut-off grades that are consistent with this. It is also very pleasing to see underlying resource growth driven by the recent discovery of a zone of higher-grade copper and gold mineralisation at the White Hill, which clearly remains open at depth and supports our exploration model targeting potential underground opportunities beyond the scope of the PFS.”

Table 1: Comparison 2023 vs 2024 Resource

Resource

| Cutoff

(% CuEq)

| Classification

| Tonnes (Mt)

| Grades | Contained Metal |

| CuEq (%) | Cu (%) | Au (g/t) | CuEq

(Mlbs) | CuEq

(kt) | Cu

(kt) | Au

(koz) |

2024

| 0.20 (OC)

0.30 (UG)

| Indicated | 890 | 0.37 | 0.26 | 0.21 | 7,300 | 3,300 | 2,300 | 6,000 |

| Inferred | 590 | 0.34 | 0.25 | 0.17 | 4,500 | 2,000 | 1,500 | 3,300 |

20231

| 0.20 (OC)

0.30 (UG)

| Indicated | 790 | 0.38 | 0.27 | 0.22 | 6,700 | 3,000 | 2,100 | 5,600 |

| Inferred | 460 | 0.37 | 0.27 | 0.19 | 3,800 | 1,700 | 1,300 | 2,900 |

Note: Figures may not sum due to rounding and significant figure do not imply an added level of precision.

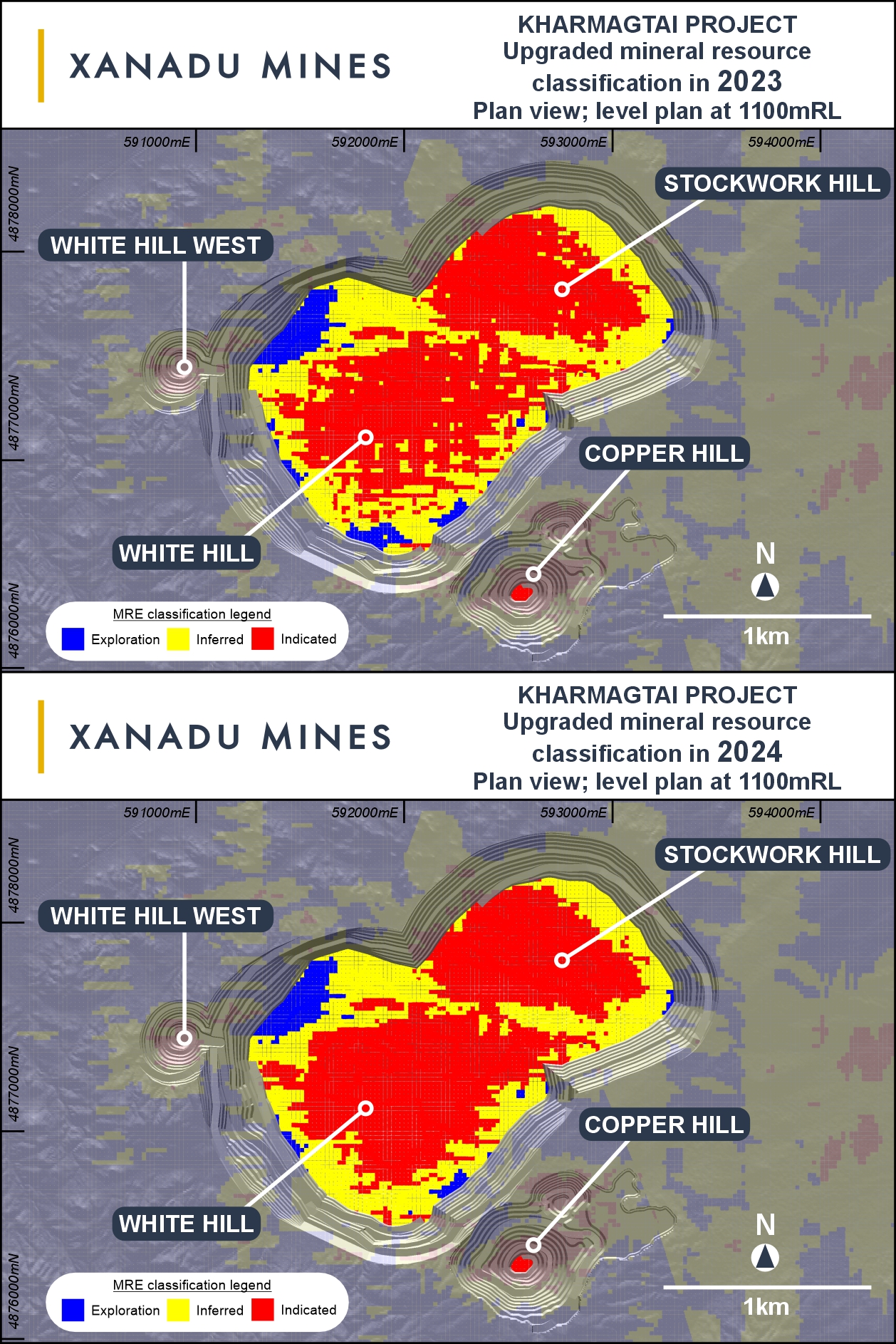

Figure 1. Resource growth in CuEq tonnes between 2023 and 2024 MRE’s. Growth attributable to additional drilling is a comparison of the 2023 and 2024 MRE’s reported using the same 2023 reporting criteria.

MINERAL RESOURCE ESTIMATE UPDATE OVERVIEW

Xanadu engaged independent consultants, Spiers Geological Consultants (SGC), to prepare an updated Resource for Kharmagtai. The Resource has been reported in accordance with the JORC Code 2012, is effective as of 31st July 2024, and is shown in full in Tables 8 to 11.

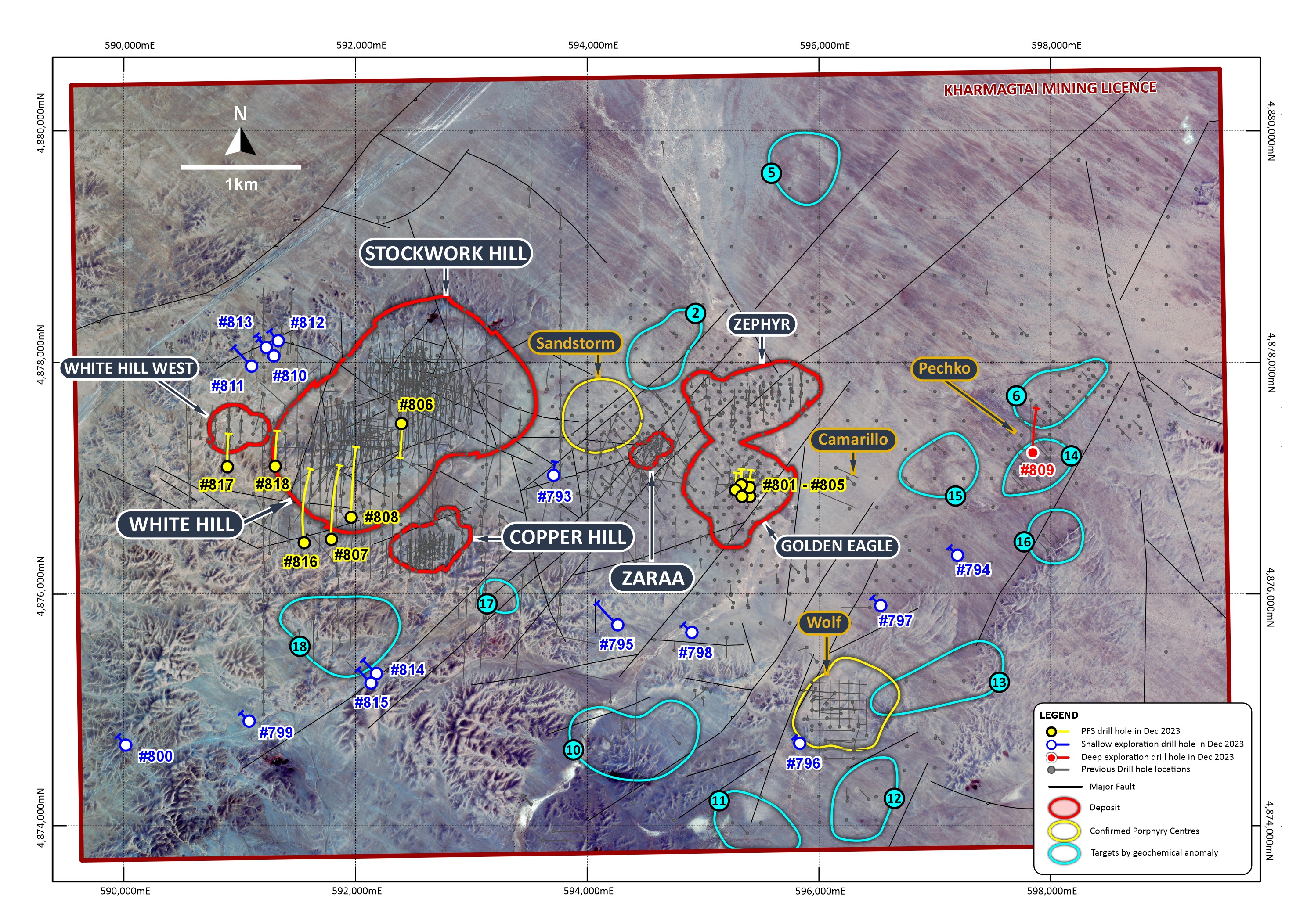

Drilling results from the past 6 months (including 11 holes for 7,300 metres of drilling) have been incorporated into an updated JORC 2012 Mineral Resource Estimate (MRE) for the Kharmagtai Copper and Gold Deposit in Mongolia (Figure 2).

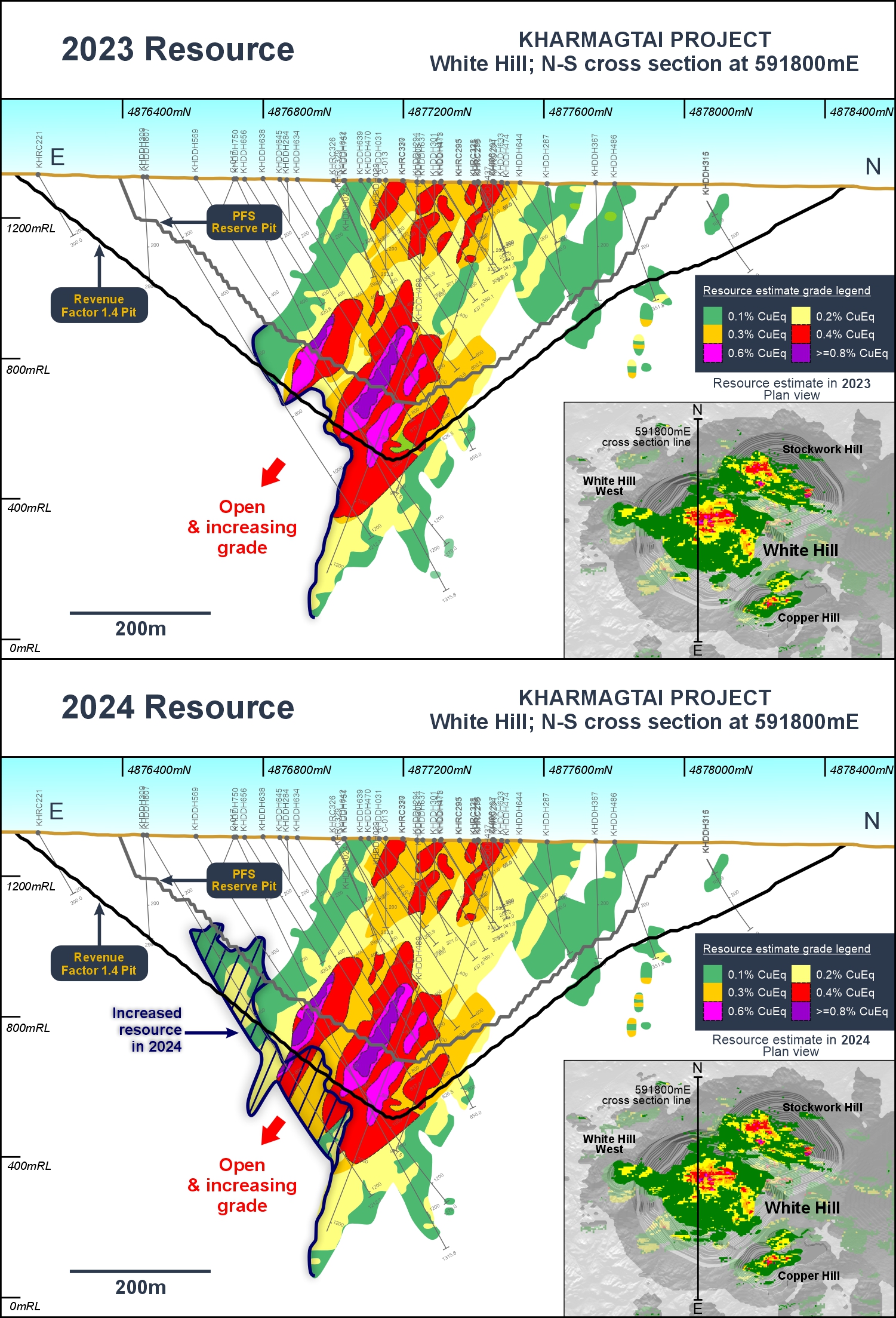

This Resource is an update to the December 2023 Mineral Resource Estimate. Results from the main body of infill drilling suggested that at White Hill the grades were increasing at depth, below the PEA designated pit and that there was potential that the orebody was shallowing towards the south. White Hill is open at depth (Figure 3), to the south and to the west. Additionally, infill drilling at Golden Eagle has linked two zones of shallow higher-grade gold mineralisation and increased the contained gold within the Golden Eagle resource.

Previous MRE estimations were reported using two different cut-off grades, for open pit (0.2%CuEq) and underground (0.3% CuEq) above and below specifically designated RL’s for each deposit. Levels were based on preliminary optimisation analysis and a 0.2% CuEq cut-off grade during the 2021 Scoping Study. The underground Resource was reported below the nominated mRL’s levels based on preliminary optimisation analysis and a 0.3% CuEq cut-off grade, reported with inside a 0.1%CuEq geological reporting wireframe. Tables 2 and 3 show the 2024 and 2023 Global Resource estimates both using the 2023 criteria described above.

Table 2. 2024 Global Resource combined for OC and UG at 0.2 and 0.3% CuEq respectively in 2023 criteria

Classification

| Tonnes

(Mt)

| Grades | Contained Metal |

CuEq

(%) | Cu

(%) | Au

(g/t) | CuEq

(Mlbs) | CuEq

(kt) | Cu

(kt) | Au

(koz) |

| Indicated | 820 | 0.38 | 0.27 | 0.22 | 6,900 | 3,100 | 2,200 | 5,700 |

| Inferred | 480 | 0.37 | 0.27 | 0.19 | 3,900 | 1,800 | 1,300 | 2,900 |

Note: Figures may not sum due to rounding and significant figure do not imply an added level of precision.

Table 3. 2023 Global Resource combined for OC and UG at 0.2 and 0.3% CuEq respectively2

Classification

| Tonnes

(Mt) | Grades | Contained Metal |

CuEq

(%) | Cu

(%) | Au

(g/t) | CuEq

(Mlbs) | CuEq

(kt) | Cu

(kt) | Au

(koz) |

| Indicated | 790 | 0.38 | 0.27 | 0.22 | 6,700 | 3,000 | 2,100 | 5,600 |

| Inferred | 460 | 0.37 | 0.27 | 0.19 | 3,800 | 1,700 | 1,300 | 2,900 |

Note: Figures may not sum due to rounding and significant figure do not imply an added level of precision.

Pit optimisations conducted to inform the ongoing PFS have defined more appropriate spatial constraints for open pit mining with the company using the revenue factor 1.4 pit shells, defined by 1.4x the expected revenue on current PFS assumptions, to inform key infrastructure decisions (i.e. all permanent infrastructure has been designed to fall outside the RF1.4 pit limits). Material falling within those pit-shells is now considered to have reasonable expectation of eventual economic extraction by open pit mining methods, therefore has been reported to a 0.2% CuEq cut-off. Material falling outside those shells continues and below the previously used RL’s are reported at the higher mass underground mining cut-off of 0.3% CuEq. Tables 4 and 5 show the 2024 Global Resource estimate using the previous and current criteria. The net effect of this change was to increase the proportion of the global resource reported at 0.2% v 0.3% (Figure 4).

Table 4. 2024 Global Resource combined for in RV1400fpit and "Other" at 0.2 and 0.3% CuEq respectively

Classification

| Tonnes (Mt)

| Grades | Contained Metal |

| CuEq (%) | Cu (%) | Au (g/t) | CuEq (Mlbs) | CuEq (kt) | Cu (kt) | Au (koz) |

| Indicated | 890 | 0.37 | 0.26 | 0.21 | 7,300 | 3,300 | 2,300 | 6,000 |

| Inferred | 590 | 0.34 | 0.25 | 0.17 | 4,500 | 2,000 | 1,500 | 3,300 |

Note: Figures may not sum due to rounding and significant figure do not imply an added level of precision.

Table 5. 2024 Global Resource combined for OC and UG at 0.2 and 0.3% CuEq respectively in 2023 criteria

Classification

| Tonnes (Mt)

| Grades | Contained Metal |

| CuEq (%) | Cu (%) | Au (g/t) | CuEq (Mlbs) | CuEq (kt) | Cu (kt) | Au (koz) |

| Indicated | 820 | 0.38 | 0.27 | 0.22 | 6,700 | 3,100 | 2,200 | 5,700 |

| Inferred | 480 | 0.37 | 0.27 | 0.19 | 3,900 | 1,800 | 1,300 | 2,900 |

Note: Figures may not sum due to rounding and significant figure do not imply an added level of precision.

SGC considers that data collection techniques are consistent with industry best practice and are suitable for use in the preparation of a Resource to be reported in accordance with JORC Code 2012. Available quality assurance and quality control (QA/QC) data supports the use of the input data provided by Xanadu.

The Resource is considered to have reasonable prospects for eventual economic extraction (RPEEE) on the following basis:

- the deposit is located in a favourable mining jurisdiction, with no known impediments to land access or tenure status; and

- the volume, orientation and grade of the Resource is amenable to mining extraction via traditional open-pit and underground methods;

The Resource models are well understood and there is substantial upside potential to be realised by better understanding the economics of the deposit. As demonstrated in the images below, significant volumes of mineralisation have been modelled that fall outside of the constraining pit wireframe. These parts of the model will be targeted for further investigation through economic studies to assess if more of this material can be brought into the Mineral Resource.

The total Mineral Resource Estimate includes material classified as oxide totalling 50Mt @ 0.34% CuEq which can be found in Table 7.

Figure 2: Plan view of the Kharmagtai district showing the additional drilling informing the 2024 MRE update.

Figure 3: Cross section through the White Hill Deposit showing resource growth and open nature of the White Hill deposit with grades generally increasing with depth. Faulting has shifted the resource towards the surface in the south, suggesting additional drilling may add significant shallower tonnes and change the shape of the current pits.

Figure 4: Schematic Cross Sections showing the cut-off grade reporting boundaries at White Hill. The 2023 December estimate was reported using a simplistic RL depth for open pit potential based on work conducted during the 2021 Scoping Study. The 2024 resource is being reported using optimised pit shapes generated during the ongoing PFS.

Tables 6-7 show the 2024 MRE in detail, with resource classification using the 2023 criteria.

Table 6: Kharmagtai Project – Potential Open Pit Mineral Resource Estimates 2024 – by resource classification using the 2023 Reporting Criteria.

Deposit

| Classification

| Tonnes

(Mt)

| Grades | Contained Metal |

CuEq

(%) | Cu

(%) | Au

(g/t) | CuEq

(Mlbs) | CuEq

(kt) | Cu

(kt) | Au

(koz) |

| SH | Indicated

| 190 | 0.42 | 0.28 | 0.28 | 1,800 | 810 | 540 | 1,700 |

| WH | 370 | 0.33 | 0.25 | 0.17 | 2,700 | 1,200 | 910 | 2,000 |

| CH | 30 | 0.42 | 0.29 | 0.25 | 260 | 120 | 80 | 230 |

| ZA | 10 | 0.26 | 0.15 | 0.23 | 50 | 20 | 10 | 60 |

| GE | 40 | 0.28 | 0.12 | 0.29 | 260 | 120 | 50 | 400 |

| ZE | 20 | 0.31 | 0.18 | 0.26 | 140 | 70 | 40 | 170 |

| PE | | | | | | | | |

| Total Indicated | 660 | 0.36 | 0.25 | 0.21 | 5,200 | 2,400 | 1,600 | 4,600 |

| SH | Inferred

| 30 | 0.30 | 0.17 | 0.24 | 200 | 90 | 50 | 230 |

| WH | 80 | 0.26 | 0.20 | 0.12 | 460 | 210 | 160 | 300 |

| CH | 10 | 0.24 | 0.20 | 0.07 | 40 | 20 | 20 | 20 |

| ZA | 10 | 0.25 | 0.15 | 0.19 | 60 | 30 | 20 | 70 |

| GE | 30 | 0.25 | 0.12 | 0.25 | 140 | 60 | 30 | 200 |

| ZE | 20 | 0.26 | 0.13 | 0.23 | 110 | 50 | 30 | 140 |

| PE | | | | | | | | |

| Total Inferred | 170 | 0.26 | 0.17 | 0.17 | 1,000 | 460 | 300 | 1,000 |

Notes:

- CuEq (lbs and t) accounts for Au (g/t) value and CuEq (t) must not be totalled to Au ounces

- Figures may not sum due to rounding

- Significant figures do not imply an added level of precision

- Resource constrained by 0.1%CuEq reporting solid inline with geological analysis by XAM

- Resource constrained by open cut above nominated mRL level by deposit as follows SH>=720mRL, WH>=915mRL, CH>=1100mRL, ZA>=920mRL, ZE>=945mRL, PE>=1100mRL and GE>=845mRL

- CuEq equation (CuEq=Cu+Au*0.60049*0.86667) where Au at USD$1400/oz and Cu at USD$3.4/lb was employed according to the Clients' (XAM) direction.

- Au recovery is relative with Cu rec=90% and Au rec=78% (rel Au rec=78/90=86.667% with number according to the Clients' (XAM) direction

Table 7: Kharmagtai Project – Potential Underground Mineral Resource Estimate 2024 – by resource classification using the 2023 Reporting Criteria.

Deposit

| Classification

| Tonnes

(Mt)

| Grades | Contained Metal |

CuEq

(%) | Cu

(%) | Au

(g/t) | CuEq

(Mlbs) | CuEq

(kt) | Cu

(kt) | Au

(koz) |

| SH | Indicated

| 30 | 0.58 | 0.35 | 0.44 | 400 | 180 | 110 | 440 |

| WH | 100 | 0.46 | 0.37 | 0.16 | 1,000 | 460 | 370 | 530 |

| CH | - | 0.37 | 0.28 | 0.18 | 30 | 10 | 10 | 20 |

| ZA | 20 | 0.47 | 0.32 | 0.28 | 250 | 110 | 80 | 220 |

| GE | - | - | - | - | - | - | - | - |

| ZE | - | - | - | - | - | - | - | - |

| PE | | | | | | | | |

| Total Indicated | 160 | 0.48 | 0.36 | 0.24 | 1,700 | 760 | 570 | 1,200 |

| SH | Inferred

| 30 | 0.42 | 0.32 | 0.20 | 260 | 120 | 90 | 180 |

| WH | 150 | 0.43 | 0.35 | 0.15 | 1,400 | 620 | 510 | 680 |

| CH | - | 0.36 | 0.30 | 0.12 | 10 | - | - | - |

| ZA | 130 | 0.43 | 0.30 | 0.25 | 1,200 | 560 | 390 | 1,000 |

| GE | - | - | - | - | - | - | - | - |

| ZE | - | 0.40 | 0.06 | 0.67 | - | - | - | - |

| PE | | | | | | | | |

| Total Inferred | 300 | 0.43 | 0.33 | 0.19 | 2,900 | 1,300 | 990 | 1,900 |

Notes:

- CuEq (lbs and t) accounts for Au (g/t) value and CuEq (t) must not be totalled to Au ounces

- Figures may not sum due to rounding

- Significant figures do not imply an added level of precision

- Resource constrained by 0.1%CuEq reporting solid inline with geological analysis by XAM

- Resource constrained by open cut above nominated mRL level by deposit as follows SH>=720mRL, WH>=915mRL, CH>=1100mRL, ZA>=920mRL, ZE>=945mRL, PE>=1100mRL and GE>=845mRL

- CuEq equation (CuEq=Cu+Au*0.60049*0.86667) where Au at USD$1400/oz and Cu at USD$3.4/lb was employed according to the Clients' (XAM) direction.

- Au recovery is relative with Cu rec=90% and Au rec=78% (rel Au rec=78/90=86.667% with number according to the Clients' (XAM) direction

Tables 8-11 show the 2024 MRE in detail, with resource classification using the 2024 criteria.

Table 8: Kharmagtai Project – Potential Open Pit Mineral Resource Estimate 2024 within the revenue factor 1.4 pit – by resource classification.

Deposit

| Classification

| Tonnes

(Mt)

| Grades | Contained Metal |

CuEq

(%) | Cu

(%) | Au

(g/t) | CuEq

(Mlbs) | CuEq

(kt) | Cu

(kt) | Au

(koz) |

| SH | Indicated

| 210 | 0.44 | 0.29 | 0.29 | 2,100 | 940 | 610 | 2,000 |

| WH | 500 | 0.35 | 0.26 | 0.16 | 3,800 | 1,700 | 1,300 | 2,600 |

| CH | 40 | 0.39 | 0.28 | 0.22 | 310 | 140 | 100 | 260 |

| ZA | 40 | 0.32 | 0.21 | 0.20 | 260 | 120 | 80 | 240 |

| GE | 40 | 0.28 | 0.12 | 0.29 | 260 | 120 | 50 | 400 |

| ZE | 20 | 0.31 | 0.18 | 0.26 | 140 | 60 | 40 | 170 |

| PE | - | - | - | - | - | - | - | - |

| Total Indicated | 850 | 0.37 | 0.26 | 0.21 | 6,900 | 3,100 | 2,200 | 5,700 |

| SH | Inferred

| 30 | 0.29 | 0.18 | 0.20 | 190 | 90 | 60 | 200 |

| WH | 210 | 0.34 | 0.27 | 0.12 | 1,500 | 700 | 570 | 820 |

| CH | 10 | 0.24 | 0.19 | 0.08 | 40 | 20 | 20 | 20 |

| ZA | 120 | 0.33 | 0.23 | 0.20 | 830 | 380 | 260 | 730 |

| GE | 20 | 0.25 | 0.12 | 0.25 | 140 | 60 | 30 | 200 |

| ZE | 10 | 0.24 | 0.15 | 0.17 | 80 | 30 | 20 | 80 |

| PE | - | - | - | - | - | - | - | - |

| Total Inferred | 400 | 0.32 | 0.24 | 0.16 | 2,800 | 1,300 | 950 | 2,000 |

Notes:

- CuEq (lbs and t) accounts for Au (g/t) value and CuEq (t) must not be totalled to Au ounces

- Figures may not sum due to rounding

- Significant figures do not imply an added level of precision

- Resource constrained by 0.1%CuEq reporting solid inline with geological analysis by XAM

- Resource constrained by RV1400fpit (coded field equal to 1)

- CuEq equation (CuEq=Cu+Au*0.60049*0.86667) where Au at USD$1400/oz and Cu at USD$3.4/lb was employed according to the Clients' (XAM) direction.

- Au recovery is relative with Cu rec=90% and Au rec=78% (rel Au rec=78/90=86.667% with number according to the Clients' (XAM) direction

- Resource "other 0p2 and 0p3" NOT inside RV1400fpit above and below nominated mRL level by deposit as follows SH>=720mRL, WH>=915mRL, CH>=1100mRL, ZA>=920mRL, ZE>=945mRL, PE>=1100mRL and GE>=845mRL

- Model: KH_ALL_GLOBAL_OKMOD_FINAL_V3_FORCLIENT_140624_inRV1400fpit

Table 9: Kharmagtai Project – Potential Open Pit Mineral Resource Estimate 2024 outside the revenue factor 1.4 pit at 0.2% CuEq– by resource classification.

Deposit

| Classification

| Tonnes

(Mt)

| Grades | Contained Metal |

CuEq

(%) | Cu

(%) | Au

(g/t) | CuEq

(Mlbs) | CuEq

(kt) | Cu

(kt) | Au

(koz) |

| SH | Indicated

| - | 0.33 | 0.19 | 0.27 | 10 | - | - | 10 |

| WH | - | 0.29 | 0.20 | 0.17 | 10 | 10 | - | 10 |

| CH | - | 0.27 | 0.19 | 0.14 | - | - | - | - |

| ZA | - | - | - | - | - | - | - | - |

| GE | - | 0.23 | 0.09 | 0.26 | - | - | - | - |

| ZE | - | 0.29 | 0.10 | 0.37 | - | - | - | - |

| PE | | | | | | | | |

| Total Indicated | - | 0.30 | 0.19 | 0.22 | 20 | 10 | - | 20 |

| SH | Inferred

| 10 | 0.39 | 0.18 | 0.41 | 50 | 20 | 10 | 70 |

| WH | 20 | 0.27 | 0.18 | 0.16 | 90 | 40 | 30 | 80 |

| CH | - | 0.26 | 0.23 | 0.06 | 10 | - | - | - |

| ZA | - | - | - | - | - | - | - | - |

| GE | - | 0.25 | 0.12 | 0.24 | 10 | - | - | 10 |

| ZE | - | 0.33 | 0.08 | 0.47 | 30 | 10 | - | 60 |

| PE | | | | | | | | |

| Total Inferred | 30 | 0.30 | 0.17 | 0.25 | 180 | 70 | 40 | 220 |

Notes:

- CuEq (lbs and t) accounts for Au (g/t) value and CuEq (t) must not be totalled to Au ounces

- Figures may not sum due to rounding

- Significant figures do not imply an added level of precision

- Resource constrained by 0.1%CuEqreporting solid inline with geological analysis by XAM

- Resource NOT constrained by RV1400fpit (coded field equal to 1)

- CuEq equation (CuEq=Cu+Au*0.60049*0.86667) where Au at USD$1400/oz and Cu at USD$3.4/lb was employed according to the Clients' (XAM) direction.

- Au recovery is relative with Cu rec=90% and Au rec=78% (rel Au rec=78/90=86.667% with number according to the Clients' (XAM) direction

- Resource "other 0p2 and 0p3" NOT inside RV1400fpit above and below nominated mRL level by deposit as follows SH>=720mRL, WH>=915mRL, CH>=1100mRL, ZA>=920mRL, ZE>=945mRL, PE>=1100mRL and GE>=845mRL

- Model: KH_ALL_GLOBAL_OKMOD_FINAL_V3_FORCLIENT_140624_inRV1400fpit

Table 10: Kharmagtai Project – Potential Underground Mineral Resource Estimate 2024 outside the revenue factor 1.4 pit at 0.3% CuEq– by resource classification.

Deposit

| Classification

| Tonnes

(Mt)

| Grades | Contained Metal |

CuEq

(%) | Cu

(%) | Au

(g/t) | CuEq

(Mlbs) | CuEq

(kt) | Cu

(kt) | Au

(koz) |

| SH | Indicated

| 10 | 0.46 | 0.30 | 0.29 | 140 | 60 | 40 | 130 |

| WH | 10 | 0.41 | 0.35 | 0.12 | 100 | 50 | 40 | 40 |

| CH | - | 0.33 | 0.23 | 0.19 | - | - | - | - |

| ZA | 10 | 0.47 | 0.33 | 0.28 | 130 | 60 | 40 | 110 |

| GE | - | - | - | - | - | - | - | - |

| ZE | - | - | - | - | - | - | - | - |

| PE | | | | | | | | |

| Total Indicated | 40 | 0.45 | 0.32 | 0.24 | 380 | 170 | 120 | 280 |

| SH | Inferred

| 30 | 0.42 | 0.32 | 0.19 | 240 | 110 | 80 | 160 |

| WH | 60 | 0.38 | 0.32 | 0.12 | 480 | 220 | 180 | 210 |

| CH | - | 0.38 | 0.34 | 0.09 | - | - | - | - |

| ZA | 80 | 0.42 | 0.30 | 0.23 | 750 | 340 | 240 | 610 |

| GE | - | - | - | - | - | - | - | - |

| ZE | - | 0.40 | 0.06 | 0.67 | - | - | - | - |

| PE | | | | | | | | |

| Total Inferred | 160 | 0.41 | 0.31 | 0.19 | 1,500 | 670 | 500 | 980 |

Notes:

- CuEq (lbs and t) accounts for Au (g/t) value and CuEq (t) must not be totalled to Au ounces

- Figures may not sum due to rounding

- Significant figuers do not imply an added level of precision

- Resource constrained by 0.1%CuEq reporting solid inline with geological analysis by XAM

- Resource NOT constrained by RV1400fpit (coded field equal to 1)

- CuEq equation (CuEq=Cu+Au*0.60049*0.86667) where Au at USD$1400/oz and Cu at USD$3.4/lb was employed according to the Clients' (XAM) direction.

- Au recovery is relative with Cu rec=90% and Au rec=78% (rel Au rec=78/90=86.667% with number according to the Clients' (XAM) direction

- Resource "other 0p2 and 0p3" NOT inside RV1400fpit above and below nominated mRL level by deposit as follows SH>=720mRL, WH>=915mRL, CH>=1100mRL, ZA>=920mRL, ZE>=945mRL, PE>=1100mRL and GE>=845mRL

- Model: KH_ALL_GLOBAL_OKMOD_FINAL_V3_FORCLIENT_140624_inRV1400fpit

Table 11: Kharmagtai Project – Oxide Mineral Resource Estimate 2024 inside the revenue factor 1.4 pit at 0.2% CuEq– by resource classification.

Deposit

| Classification

| Tonnes

(Mt)

| Grades | Contained Metal |

CuEq

(%) | Cu

(%) | Au

(g/t) | CuEq

(Mlbs) | CuEq

(kt) | Cu

(kt) | Au

(koz) |

| SH | Indicated

| 10 | 0.38 | 0.25 | 0.26 | 74 | 30 | 20 | 70 |

| WH | 30 | 0.32 | 0.24 | 0.16 | 180 | 80 | 60 | 130 |

| CH | 10 | 0.42 | 0.31 | 0.21 | 55 | 20 | 20 | 40 |

| ZA | - | 0.33 | 0.12 | 0.40 | 6 | - | - | 10 |

| GE | - | 0.33 | 0.11 | 0.42 | 26 | 10 | - | 50 |

| ZE | - | 0.32 | 0.20 | 0.24 | 20 | 10 | - | 20 |

| PE | - | 0.26 | 0.13 | 0.24 | - | - | - | - |

| Total Indicated | 50 | 0.34 | 0.23 | 0.21 | 360 | 170 | 110 | 330 |

| SH | Inferred

| - | 0.25 | 0.14 | 0.20 | - | - | - | - |

| WH | - | 0.29 | 0.22 | 0.14 | 10 | - | - | 10 |

| CH | - | 0.24 | 0.20 | 0.07 | - | - | - | - |

| ZA | - | 0.29 | 0.13 | 0.30 | - | - | - | - |

| GE | - | 0.26 | 0.10 | 0.31 | 10 | - | - | 20 |

| ZE | - | 0.21 | 0.05 | 0.31 | - | - | - | - |

| PE | - | 0.23 | 0.11 | 0.24 | - | - | - | - |

| Total Inferred | - | 0.27 | 0.16 | 0.20 | 30 | 10 | 10 | 30 |

Notes:

- CuEq (lbs and t) accounts for Au (g/t) value and CuEq (t) must not be totalled to Au ounces

- Figures may not sum due to rounding

- Significant figures do not imply an added level of precision

- Resource constrained by 0.1%CuEq reporting solid inline with geological analysis by XAM

- Resource constrained by RV1400fpit (coded field equal to 1)

- CuEq equation (CuEq=Cu+Au*0.60049*0.86667) where Au at USD$1400/oz and Cu at USD$3.4/lb was employed according to the Clients' (XAM) direction.

- Au recovery is relative with Cu rec=90% and Au rec=78% (rel Au rec=78/90=86.667% with number according to the Clients' (XAM) direction

- Resource "other 0p2 and 0p3" NOT inside RV1400fpit above and below nominated mRL level by deposit as follows SH>=720mRL, WH>=915mRL, CH>=1100mRL, ZA>=920mRL, ZE>=945mRL, PE>=1100mRL and GE>=845mRL

- Model: KH_ALL_GLOBAL_OKMOD_FINAL_V3_FORCLIENT_140624_inRV1400fpit

ESTIMATE METHODOLOGY

The Kharmagtai resource models have been estimated by Ordinary Kriging (OK) using third party software and are post processed in SGC’s preferred software. An internal process review was conducted by SGC and no third-party modelling was undertaken at this time.

Data searches were aligned consistent with the strike, dip and plunge (where appropriate) of the mineralisation consistent with the domain and geometry modelling as a result of the detailed geological investigation put forth by Xanadu (the Client).

According to the Client’s interpretation, the mineralisation host exhibit geometries which are consistent with those geometries defined by the spatial analysis of grade (in this instance Copper, Gold, Molybdenum and Sulphur).

A nominal composite length of 4 metre down hole was used for inputs which was settled upon during consultation with the Client and the Client’s preferred Geological Consultant team.

Where appropriate data was transformed and geometry modelling and variograms of the variables were calculated and modelled.

Several iterations of the modelling process were undertaken to assess the sensitivity of estimates to estimation parameters. Post processing, model validation and reporting were undertaken in SGC’s preferred third party software in-line with the Client’s end use.

Ordinary kriging of the variables was performed in the UTM_47N grid. Block dimensions were selected in line with data density and modelling methodology as well as taking into account potential mining methodologies. Search and data criteria were assessed and implemented, in-line with modelling strategy. Models were constructed and iteration undertaken to assess modelling sensitivities to data and search criteria.

The block estimates were validated against the informing data to ensure that they were consistent with the original informing data in a three-dimensional sense and within the search neighbourhood via data analysis.

The block estimates were exported to SGC’s preferred third party software and where appropriate, a topographic surface was applied as were other surfaces and solids which may have acted upon the estimates. Each model area was then compiled into a global model where all fields underwent secondary validation and data/s were assigned (where deemed appropriate by SGC in consultation with the Client’s geological team) as well as coding for primary domain and the calculation of Cu% and CuEq% were completed.

Final densities were assigned where necessary and model validation completed ahead of final report preparation.

Individual blocks in the resource models (within the Global Kharmagtai Resource Model) have been allocated a resource classification of Indicated and Inferred confidence category based on the consideration of the number and location of data used to estimate the grade of each block in-line with the modelling approach established during the week-long collaboration between XAM staff, SGC and a third-party representative on behalf of XAM. In addition, further consideration incorporated into the resource classification discussion included (but not limited to) the following aspects, quality control and assurances (both internal to XAM and the associated laboratories employed as well as third party laboratory analysis) relating to sampling, sample handling, sample preparation and analysis, database administration and validation. The resource classification also takes into account structural complexity and the associated geological models and constraining solids, as well as population distributions and geometry.

Figure 5: Illustration of resource classification within the 2024 PFS pit shells.

About Xanadu Mines

Xanadu is an ASX and TSX listed Exploration company operating in Mongolia. We give investors exposure to globally significant, large-scale copper-gold discoveries and low-cost inventory growth. Xanadu maintains a portfolio of exploration projects and remains one of the few junior explorers on the ASX or TSX who jointly control a globally significant copper-gold deposit in our flagship Kharmagtai project. Xanadu is the Operator of a 50-50 JV with Zijin Mining Group in Khuiten Metals Pte Ltd, which controls 76.5% of the Kharmagtai project.

For further information, please contact:

Colin Moorhead

Executive Chairman & Managing Director

E: colin.moorhead@xanadumines.com

P: +61 2 8280 7497

This Announcement was authorised for release by Xanadu’s Executive Chair & Managing Director.

Forward-Looking Statements

Certain statements contained in this Announcement, including information as to the future financial or operating performance of Xanadu and its projects may also include statements which are ‘forward‐looking statements’ that may include, amongst other things, statements regarding targets, estimates and assumptions in respect of mineral reserves and mineral resources and anticipated grades and recovery rates, production and prices, recovery costs and results, capital expenditures and are or may be based on assumptions and estimates related to future technical, economic, market, political, social and other conditions. These ‘forward-looking statements’ are necessarily based upon a number of estimates and assumptions that, while considered reasonable by Xanadu, are inherently subject to significant technical, business, economic, competitive, political and social uncertainties and contingencies and involve known and unknown risks and uncertainties that could cause actual events or results to differ materially from estimated or anticipated events or results reflected in such forward‐looking statements.

Xanadu disclaims any intent or obligation to update publicly or release any revisions to any forward‐looking statements, whether as a result of new information, future events, circumstances or results or otherwise after the date of this Announcement or to reflect the occurrence of unanticipated events, other than required by the Corporations Act 2001 (Cth) and the Listing Rules of the Australian Securities Exchange (ASX) and Toronto Stock Exchange (TSX). The words ‘believe’, ‘expect’, ‘anticipate’, ‘indicate’, ‘contemplate’, ‘target’, ‘plan’, ‘intends’, ‘continue’, ‘budget’, ‘estimate’, ‘may’, ‘will’, ‘schedule’ and similar expressions identify forward‐looking statements.

All ‘forward‐looking statements’ made in this Announcement are qualified by the foregoing cautionary statements. Investors are cautioned that ‘forward‐looking statements’ are not guarantee of future performance and accordingly investors are cautioned not to put undue reliance on ‘forward‐looking statements’ due to the inherent uncertainty therein.

For further information please visit the Xanadu Mines’ Website at www.xanadumines.com.

APPENDIX 1: COMPETENT PERSON’S STATEMENT

Mr Robert Spiers is a full time Principal Geologist employed by Spiers Geological Consultants (SGC), 4 Martin Street, Mount Martha, Victoria, Australia. Mr Spiers is contracted on a consulting basis by Xanadu Mines.

Mr Spiers graduated with a Bachelor of Science (BSc) Honours and a double Major of Geology and Geophysics from Latrobe University, Melbourne, Victoria, Australia and has been a member of the Australian Institute of Geoscientists for 26 years; working as a Geologist for in-excess of 30 years since graduating.

Mr Spiers has sufficient experience that is relevant to the style of mineralisation and type of deposit under consideration and to the activity being undertaking to qualify as a Competent Person as defined in the 2012 Edition of the ‘Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves’. Mr Spiers consents to the inclusion in the report to which this statement is to be attached of the matters based on his information in the form and context in which it appears.

The information in the report to which this statement is to be attached that relates to Mineral Resources is based on information compiled by Mr Robert Spiers, a Competent Person who is a Member of the Australian Institute of Geoscientists or a ‘Recognised Professional Organisation’ (RPO) included in a list posted on the ASX website from time to time.

Mr Spiers consents to the disclosure of this information on the page/s in the form and context in which it appears.

To the best Mr Spiers knowledge, neither SGC, himself and / or other related parties have any conflict of interest with by XAM in accordance with the transparency principle set out by the JORC code and supported by ASX rulings.

In relation to the above statement, Mr Spiers holds 750,000 ordinary shares in the ASX listed XAM entity purchased on market in accordance with the XAM trading policy (guidance notes 27). The aforementioned shareholding does not constitute a material holding in the company in question.

Mr Spiers has read the definition of “competent person” set out in the JORC code and guidelines for the reporting of Mineral Resource Estimates and certify that by reason of his education, affiliation with a professional association (MAIG) and past relevant work experience, that he fulfils the requirements of a “Competent Person” for the purposes of JORC 2012.

As of the date of this document, to the best of Mr Spiers knowledge, information and belief, the Public Release / Technical Report to which this statement is to be attached (in relation to the Reporting of the Kharmagtai Mineral Resource Estimation December 2023) contains all the scientific and technical information that is required to be disclosed in relation to the Mineral Resources to make the Public Release / Technical Report not misleading with respect to the sections for which Mr Spiers is responsible.

Dated the 21st day of August 2024.

__________________________

Robert Spiers, BSc Hons, MAIG

Our Customer

This report has been produced by or on behalf of Spiers Geological Consultants (SGC) for the sole use by Xanadu Mines (XAM or the Customer). The Customer’s use and disclosure of this report is subject to the terms and conditions under which SGC prepared the report. All items in the report must if used in a third-party report be taken in context and consent from SGC must be sought on each occasion.

Notice to Third Parties

SGC prepared this report for the Customer only. If you are not the Customer:

- SGC have prepared this report having regard to the particular needs and interests of the Customer, and in accordance with the Customer’s instructions. It did not draft this report having regard to any other person’s particular needs or interests. Your needs and interests may be distinctly different to the Customer’s needs and interests, and the report may not be sufficient, fit or appropriate for your purposes.

- SGC does not make and expressly disclaims from making any representation or warranty to you – express or implied regarding this report or the conclusions or opinions set out in this report (including without limitation any representation or warranty regarding the standard of care used in preparing this report, or that any forward-looking statements, forecasts, opinions or projections contained in the report will be achieved, will prove to be correct or are based on reasonable assumptions).

- SGC expressly disclaim any liability to you and any duty of care to you.

- SGC does not authorise you to rely on this report. If you choose to use or rely on all or part of this report, then any loss or damage you may suffer in so doing is at your sole and exclusive risk.

Inputs, Subsequent Changes and No Duty to Update

SGC have created this report using data and information provided by or on behalf of the Customer [and Customer’s agents and contractors]. Unless specifically stated otherwise, SGC has not independently verified that data and information unless expressly noted. SGC accepts no liability for the accuracy or completeness of that data and information, even if that data and information has been incorporated into or relied upon in creating this report (or parts of it).

The conclusions and opinions contained in this report apply as at the date of the report. Events (including changes to any of the data and information that SGC used in preparing the report) may have occurred since that date which may impact on those conclusions and opinions and make them unreliable. SGC is under no duty to update the report upon the occurrence of any such event, though it reserves the right to do so.

Mining Unknown Factors

The ability of any person to achieve forward-looking production and economic targets is dependent on numerous factors that are beyond SGC’s control and that SGC cannot anticipate. These factors include, but are not limited to, site-specific mining and geological conditions, management and personnel capabilities, availability of funding to properly operate and capitalize the operation, variations in cost elements and market conditions, developing and operating the mine in an efficient manner, unforeseen changes in legislation and new industry developments. Any of these factors may substantially alter the performance of any mining operation.

APPENDIX 2: ADDITIONAL STATEMENTS AND DISCLAIMERS

Mineral Resources and Ore Reserves Reporting Requirements

The 2012 Edition of the Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves (the JORC Code 2012) sets out minimum standards, recommendations and guidelines for Public Reporting in Australasia of Exploration Results, Mineral Resources and Ore Reserves. The Information contained in this Announcement has been presented in accordance with the JORC Code 2012.

The information in this Announcement relates to the exploration results previously reported in ASX Announcements which are available on the Xanadu website at:

https://www.xanadumines.com/site/investor-centre/asx-announcements

The Company is not aware of any new, material information or data that is not included in those market announcements.

Copper Equivalent Calculations

The copper equivalent (CuEq or eCu) calculation represents the total metal value for each metal, multiplied by the conversion factor, summed and expressed in equivalent copper percentage with a metallurgical recovery factor applied.

Copper equivalent grade values were calculated using the following formula:

CuEq or eCu = Cu + Au * 0.60049 * 0.86667,

Gold Equivalent (eAu) grade values were calculated using the following formula:

eAu = Au + Cu / 0.60049 * 0.86667.

Where:

Cu - copper grade (%)

Au - gold grade (g/t)

0.60049 - conversion factor (gold to copper)

0.86667 - relative recovery of gold to copper (86.67%)

The copper equivalent formula was based on the following parameters (prices are in USD):

- Copper price - 3.4 $/lb

- Gold price - 1400 $/oz

- Copper recovery - 90%

- Gold recovery - 78%

Relative recovery of gold to copper = 78% / 90% = 86.67%.

APPENDIX 3: KHARMAGTAI TABLE 1 (JORC 2012)

Set out below is Section 1 and Section 2 of Table 1 under the JORC Code, 2012 Edition for the Kharmagtai project. Data provided by Xanadu. This Table 1 updates the JORC Table 1 disclosure dated 8 December 2023.

JORC TABLE 1 - SECTION 1 - SAMPLING TECHNIQUES AND DATA

(Criteria in this section apply to all succeeding sections).

| Criteria | Commentary |

| Sampling techniques | - Representative ½ core samples were split from PQ, HQ & NQ diameter diamond drill core on site using rock saws, on a routine 2m sample interval that also honours lithological/intrusive contacts.

- The orientation of the cut line is controlled using the core orientation line ensuring uniformity of core splitting wherever the core has been successfully oriented.

- Sample intervals are defined and subsequently checked by geologists, and sample tags are attached (stapled) to the plastic core trays for every sample interval.

- Reverse Circulation (RC) chip samples are ¼ splits from one meter (1m) intervals using a 75%:25% riffle splitter to obtain a 3kg sample

- RC samples are uniform 2m samples formed from the combination of two ¼ split 1m samples.

|

| Drilling techniques | - The Mineral Resource Estimation has been based upon diamond drilling of PQ, HQ and NQ diameters with both standard and triple tube core recovery configurations, RC drilling and surface trenching with channel sampling.

- All drill core drilled by Xanadu has been oriented using the “Reflex Ace” tool.

|

| Drill sample recovery | - Diamond drill core recoveries were assessed using the standard industry (best) practice which involves removing the core from core trays; reassembling multiple core runs in a v-rail; measuring core lengths with a tape measure, assessing recovery against core block depth measurements and recording any measured core loss for each core run.

- Diamond core recoveries average 97% through mineralisation.

- Overall, core quality is good, with minimal core loss. Where there is localised faulting and or fracturing core recoveries decrease, however, this is a very small percentage of the mineralised intersections.

- RC recoveries are measured using whole weight of each 1m intercept measured before splitting

- Analysis of recovery results vs grade shows no significant trends that might indicate sampling bias introduced by variable recovery in fault/fracture zones.

|

| Logging | - All drill core is geologically logged by well-trained geologists using a modified “Anaconda-style” logging system methodology. The Anaconda method of logging and mapping is specifically designed for porphyry Cu-Au mineral systems and is entirely appropriate to support Mineral Resource Estimation, mining and metallurgical studies.

- Logging of lithology, alteration and mineralogy is intrinsically qualitative in nature. However, the logging is subsequently supported by 4 Acid ICP-MS (48 element) geochemistry and SWIR spectral mineralogy (facilitating semi-quantitative/calculated mineralogical, lithological and alteration classification) which is integrated with the logging to improve cross section interpretation and 3D geological model development.

- Drill core is also systematically logged for both geotechnical features and geological structures. Where drill core has been successfully oriented, the orientation of structures and geotechnical features are also routinely measured.

- Both wet and dry core photos are taken after core has been logged and marked-up but before drill core has been cut.

|

| Sub-sampling techniques and sample preparation | - All drill core samples are ½ core splits from either PQ, HQ or NQ diameter cores. A routine 2m sample interval is used, but this is varied locally to honour lithological/intrusive contacts. The minimum allowed sample length is 30cm.

- Core is appropriately split (onsite) using diamond core saws with the cut line routinely located relative to the core orientation line (where present) to provide consistency of sample split selection.

- The diamond saws are regularly flushed with water to minimize potential contamination.

- A field duplicate ¼ core sample is collected every 30th sample to ensure the “representivity of the in-situ material collected”. The performance of these field duplicates is routinely analysed as part of Xanadu’s sample QC process.

- Routine sample preparation and analyses of DDH samples were carried out by ALS Mongolia LLC (ALS Mongolia), who operates an independent sample preparation and analytical laboratory in Ulaanbaatar.

- All samples were prepared to meet standard quality control procedures as follows: Crushed to 75% passing 2mm, split to 1kg, pulverised to 85% passing 200 mesh (75 microns) and split to 150g sample pulp.

- ALS Mongolia Geochemistry labs quality management system is certified to ISO 9001:2008.

- The sample support (sub-sample mass and comminution) is appropriate for the grainsize and Cu-Au distribution of the porphyry Cu-Au mineralization and associated host rocks.

|

| Quality of assay data and laboratory tests | - All samples were routinely assayed by ALS Mongolia for gold

- Au is determined using a 25g fire assay fusion, cupelled to obtain a bead, and digested with Aqua Regia, followed by an atomic absorption spectroscopy (AAS) finish, with a lower detection (LDL) of 0.01 ppm.

- All samples were also submitted to ALS Mongolia for the 48-element package ME-ICP61 using a four-acid digest (considered to be an effective total digest for the elements relevant to the Mineral Resource Estimate (MRE)). Where copper is over-range (>1% Cu), it is analysed by a second analytical technique (Cu-OG62), which has a higher upper detection limit (UDL) of 5% copper.

- Quality assurance has been managed by insertion of appropriate Standards (1:30 samples – suitable Ore Research Pty Ltd certified standards), Blanks (1:30 samples), Duplicates (1:30 samples – ¼ core duplicate) by XAM.

- Assay results outside the optimal range for methods were re-analysed by appropriate methods.

- Ore Research Pty Ltd certified copper and gold standards have been implemented as a part of QC procedures, as well as coarse and pulp blanks, and certified matrix matched copper-gold standards.

- QC monitoring is an active and ongoing processes on batch-by-batch basis by which unacceptable results are re-assayed as soon as practicable.

- Prior to 2014: Cu, Ag, Pb, Zn, As and Mo were routinely determined using a three-acid-digestion of a 0.3g sub-sample followed by an AAS finish (AAS21R) at SGS Mongolia. Samples were digested with nitric, hydrochloric and perchloric acids to dryness before leaching with hydrochloric acid to dissolve soluble salts and made to 15ml volume with distilled water. The LDL for copper using this technique was 2ppm. Where copper was over-range (>1% Cu), it was analysed by a second analytical technique (AAS22S), which has a higher upper detection limit (UDL) of 5% copper. Gold analysis method was essentially unchanged.

|

| Verification of sampling and assaying | - All assay data QA/QC is checked prior to loading into XAM’s Geobank data base.

- The data is managed by XAM geologists.

- The data base and geological interpretation is managed by XAM.

- Check assays are submitted to an umpire lab (SGS Mongolia) for duplicate analysis.

- No twinned drill holes exist.

- There have been no adjustments to any of the assay data.

|

| Location of data points | - Diamond drill holes have been surveyed with a differential global positioning system (DGPS) to within 10cm accuracy.

- The grid system used for the project is UTM WGS-84 Zone 48N

- Historically, Eastman Kodak and Flexit electronic multi-shot downhole survey tools have been used at Kharmagtai to collect down hole azimuth and inclination information for the majority of the diamond drill holes. Single shots were typically taken every 30m to 50m during the drilling process, and a multi-shot survey with readings every 3-5m are conducted at the completion of the drill hole. As these tools rely on the earth’s magnetic field to measure azimuth, there is some localised interference/inaccuracy introduced by the presence of magnetite in some parts of the Kharmagtai mineral system. The extent of this interference cannot be quantified on a reading-by-reading basis.

- More recently (since September 2017), a north-seeking gyro has been employed by the drilling crews on site (rented and operated by the drilling contractor), providing accurate downhole orientation measurements unaffected by magnetic effects. Xanadu have a permanent calibration station setup for the gyro tool, which is routinely calibrated every 2 weeks (calibration records are maintained and were sighted)

- The project Digital Terrain Model (DTM) is based on 1m contours from satellite imagery with an accuracy of ±0.1 m.

|

| Data spacing and distribution | - Holes spacings range from <50m spacings within the core of mineralization to +500m spacings for exploration drilling. Hole spacings can be determined using the sections and drill plans provided.

- Holes range from vertical to an inclination of -60 degrees depending on the attitude of the target and the drilling method.

- The data spacing and distribution is sufficient to establish anomalism and targeting for porphyry Cu-Au, tourmaline breccia and epithermal target types.

- Holes have been drilled to a maximum of 1,400m vertical depth.

- The data spacing and distribution is sufficient to establish geological and grade continuity, and to support the Mineral Resource classification.

|

| Orientation of data in relation to geological structure | - Drilling is conducted in a predominantly regular grid to allow unbiased interpretation and targeting.

- Scissor drilling, as well as some vertical and oblique drilling, has been used in key mineralised zones to achieve unbiased sampling of interpreted structures and mineralised zones, and in particular to assist in constraining the geometry of the mineralised hydrothermal tourmaline-sulphide breccia domains.

|

| Sample security | - Samples are delivered from the drill rig to the core shed twice daily and are never left unattended at the rig.

- Samples are dispatched from site in locked boxes transported on XAM company vehicles to ALS lab in Ulaanbaatar.

- Sample shipment receipt is signed off at the Laboratory with additional email confirmation of receipt.

- Samples are then stored at the lab and returned to a locked storage site.

|

| Audits or reviews | - Internal audits of sampling techniques and data management are undertaken on a regular basis, to ensure industry best practice is employed at all times.

- External reviews and audits have been conducted by the following groups:

- 2012: AMC Consultants Pty Ltd. was engaged to conduct an Independent Technical Report which reviewed drilling and sampling procedures. It was concluded that sampling and data record was to an appropriate standard.

- 2013: Mining Associates Ltd. was engaged to conduct an Independent Technical Report to review drilling, sampling techniques and QAQC. Methods were found to conform to international best practice.

- 2018: CSA Global reviewed the entire drilling, logging, sampling, sample shipping and laboratory processes during the competent persons site visit for the 2018 MRE and found the systems and adherence to protocols to be to an appropriate standard.

|

JORC TABLE 1 - SECTION 2 - REPORTING OF EXPLORATION RESULTS

(Criteria in this section apply to all succeeding sections).

| Criteria | Commentary |

Mineral

tenement

and land

tenure

status | - The Project comprises 2 Mining Licences (MV-17129A Oyut Ulaan and (MV-17387A Kharmagtai):

- Xanadu now owns 100% of Vantage LLC, the 100% owner of the Oyut Ulaan mining licence.

- The Kharmagtai mining license MV-17387A is 100% owned by Oyut Ulaan LLC. Xanadu has an 85% interest in Mongol Metals LLC, which has 90% interest in Oyut Ulaan LLC. The remaining 10% in Oyut Ulaan LLC is owned by Quincunx (BVI) Ltd (“Quincunx”).

- The Mongolian Minerals Law (2006) and Mongolian Land Law (2002) govern exploration, mining and land use rights for the project.

|

Exploration

done by

other

parties | - Previous exploration at Kharmagtai was conducted by Quincunx Ltd, Ivanhoe Mines Ltd and Turquoise Hill Resources Ltd including extensive drilling, surface geochemistry, geophysics, mapping.

- Previous exploration at Red Mountain (Oyut Ulaan) was conducted by Ivanhoe Mines.

|

Geology

| - The mineralisation is characterised as porphyry copper-gold type.

- Porphyry copper-gold deposits are formed from magmatic hydrothermal fluids typically associated with felsic intrusive stocks that have deposited metals as sulphides both within the intrusive and the intruded host rocks. Quartz stockwork veining is typically associated with sulphides occurring both within the quartz veinlets and disseminated thought out the wall rock. Porphyry deposits are typically large tonnage deposits ranging from low to high grade and are generally mined by large scale open pit or underground bulk mining methods. The deposits at Kharmagtai are atypical in that they are associated with intermediate intrusions of diorite to quartz diorite composition; however, the deposits are in terms of contained gold significant, and similar gold-rich porphyry deposits.

|

Drill hole

Information | - Diamond drill holes are the principal source of geological and grade data for the Project.

- See figures in this ASX/TSX Announcement.

|

Data

Aggregation methods | - A nominal cut-off of 0.1% eCu is used in copper dominant systems for identification of potentially significant intercepts for reporting purposes. Higher grade cut-offs are 0.3%, 0.6% and 1% eCu.

- A nominal cut-off of 0.1g/t eAu is used in gold dominant systems like Golden Eagle for identification of potentially significant intercepts for reporting purposes. Higher grade cut-offs are 0.3g/t, 0.6g/t and 1g/t eAu.

- Maximum contiguous dilution within each intercept is 9m for 0.1%, 0.3%, 0.6% and 1% eCu.

- Most of the reported intercepts are shown in sufficient detail, including maxima and subintervals, to allow the reader to make an assessment of the balance of high and low grades in the intercept.

- Informing samples have been composited to two metre lengths honouring the geological domains and adjusted where necessary to ensure that no residual sample lengths have been excluded (best fit).

The copper equivalent (CuEq or eCu) calculation represents the total metal value for each metal, multiplied by the conversion factor, summed and expressed in equivalent copper percentage with a metallurgical recovery factor applied.

Copper equivalent (CuEq or eCu) grade values were calculated using the following formula:

eCu or CuEq = Cu + Au * 0.60049 * 0.86667,

Gold Equivalent (eAu) grade values were calculated using the following formula:

eAu = Au + Cu / 0.60049 * 0.86667.

Where:

Cu - copper grade (%)

Au - gold grade (g/t)

0.60049 - conversion factor (gold to copper)

0.86667 - relative recovery of gold to copper (86.67%)

The copper equivalent formula was based on the following parameters (prices are in USD): - Copper price - 3.4 $/lb

- Gold price - 1400 $/oz

- Copper recovery - 90%

- Gold recovery - 78%

- Relative recovery of gold to copper = 78% / 90% = 86.67%.

|

Relationship between mineralisation

on widths

and intercept

lengths | - Mineralised structures are variable in orientation, and therefore drill orientations have been adjusted from place to place in order to allow intersection angles as close as possible to true widths.

- Exploration results have been reported as an interval with 'from' and 'to' stated in tables of significant economic intercepts. Tables clearly indicate that true widths will generally be narrower than those reported.

|

| Diagrams | - See figures in the body of this ASX/TSX Announcement.

|

Balanced

reporting | - Resources have been reported at a range of cut-off grades, above a minimum suitable for open pit mining, and above a minimum suitable for underground mining.

|

Other

substantive

exploration

data | - Extensive work in this area has been done and is reported separately.

|

Further

Work | - The mineralisation is open at depth and along strike.

- Current estimates are restricted to those expected to be reasonable for open pit mining. Limited drilling below this depth (-300m RLl) shows widths and grades potentially suitable for underground extraction.

- Exploration on going.

|

JORC TABLE 1 - SECTION 3 - ESTIMATION AND REPORTING OF MINERAL RESOURCES

| Criteria | Commentary |

| Database integrity | The database is managed using Micromine Geobank software. Data is logged directly into an Excel spread sheet logging system with drop down field lists. Validation checks are written into the importing program ensures all data is of high quality. Digital assay data is obtained from the Laboratory, QA/QC checked and imported. Geobank exported to CSV TEXT and imported directly to the Micromine software used for the MRE.

- The combined database was provided for the MRE.

- Validation of the data import include checks for the following: o Duplicate drill hole or trench names,

- One or more drill hole collar or trench coordinates missing in the collar file,

- FROM or TO missing or absent in the assay file,

- FROM > TO in the assay file,

- Sample intervals overlap in the assay file,

- First sample is not equal to 0 m in the assay file,

- First depth is not equal to 0 m in the survey file,

- Several downhole survey records exist for the same depth,

- Azimuth is not between 0 and 360° in the survey file,

- Dip is not between 0 and 90° in the survey file,

- Azimuth or dip is missing in survey file,

- Total depth of the holes is less than the depth of the last sample,

- Total length of trenches is less than the total length of all samples.

- Negative sample grades.

- No logical errors were identified in the analytical data.

|

| Site visits | - Site visits was conducted by SGC during the period 5th of September 2022 through to the 16th of September 2022.

|

| Geological interpretation | Geological data has been collected in a consistent manner that has allowed the development of geological models to support the Mineral Resource estimate. Copper and gold mineralisation is controlled by porphyry phases, oxidation zone, the level of veining, breccia, country rocks and barren dykes.

- Solid geological models were generated in Leapfrog for each of the deposits using the following methodology

- Composite copper and gold grades to 10m intervals

- Define cut-offs using changes in slope of histograms and cumulative log plots

- Create raw grade shells for these using implicit numeric modelling (e.g. 800, 1500 and 4000ppm Cu)

- Define the main dividing features/structures between populations (clusters of grade)

- Build these structures in detail using grade, lithology, and structural information

- For each compartment/fault block

- Group the main lithologies into “like units”

- Build geological shapes from these units

- Re-build the grade shells within each compartment using information from the geological shapes to help constrain the grade shapes

- Once each compartment was built, they were assessed in context with each other and refined so that the models made geological sense.

- Geological interpretation and wireframing were based on sampling results of drill holes and trenches, which were logged at 2 m intervals (average, tied to lithological boundaries during logging).

- SGC do not believe that the effect of alternative interpretations

- SGC do not believe that the effect of alternative interpretations will have a material impact on the overall Mineral Resource Estimates.

- The geological interpretation is considered robust & alternative interpretations are not considered to have a material effect on the Mineral Resource. No alternate interpretations are proposed as geological confidence in the model is moderate to high. As additional geological data is collected from additional drilling, the geological interpretation will be continually updated.

- The factors affecting continuity both of grade and geology are most likely to be associated with structural controls and local complexity the knowledge of which is considered at a moderate level with the current spacing of information. The broad approach to the mineralisation modelling is an attempt to model an unbiased interpretation.

|

| Dimensions | - Stockwork Hill: The strike length of the mineralised zone is about 1,350 m. Width is up to 800 m, traced down dip to 1,250 m. Mineralisation outcrops at the surface.

- White Hill: The strike length of the mineralised zone is about 1,800 m. Width is up to 830 m, traced down dip to 1,210 m. Mineralisation outcrops at the surface.

- Copper Hill: The strike length of the mineralised zone is about 630 m. Width is up to 150 m with apparent plunging to SW at about 40 degrees. traced down dip to 420 m dipping 70 degrees to SE. Mineralisation is outcropped at the surface.

- Zaraa: The strike length of the mineralised zone is about 1,300m. Width is up to 600m with apparent plunging to SW at about 60 degrees. traced down dip to 1,280m dipping. Mineralisation outcrops at the basement surface, beneath 35m of Palaeozoic cover.

- Golden Eagle: The strike length of the mineralised zone is about 400m. Width is up to 400m. traced down dip to 450 m. Mineralisation outcrops at the basement surface, beneath 35m of Palaeozoic cover.

- Zephyr: The strike length of the mineralised zone is about 1,030 m. Width is up to 310 m. Traced down dip to 350m. SE. Mineralisation outcrops at the basement surface, beneath 30m of Palaeozoic cover.

|

| Estimation and modelling techniques | - Ordinary Kriging technique was employed using third party software based on low coefficient of variation between samples in the mineralised domain.

- Grade interpolation and search ellipses were based on variography and geometry modelling outcomes.

- Modelling was conducted in three passes with block sizes being 20.0 m E by 20.0 m N by 10.0 m RL; discretisation was 5x5x2 for all project areas

- In the first pass data and octant criteria used were, Minimum Data=12, maximum Data=32, Minimum Octants=4. Search radii was 55 mE by 75 mN by 10 mRL.

- An expansion factor of 1 was applied so in the second pass saw the same data and octants criteria with an expanded search to 110mE by 150mN by 20mRL.

- The third pass saw Minimum Data=6, maximum Data=32, Minimum Octants=2. Search radii was 110mE by 150mN by 20mRL.

- Top cutting was applied to domains and elements which displayed a very strongly skewed nature as summarise in the report reference and in accordance with the prevailing coefficients of variation.

- Secondary attributes including the modelling of density which was also modelled on three passes (as above) which included the same data and octant criteria as above.

- No dilution was expressly added to the SGC model however domain was largely driven by geological and grade domains created by the Client (XM) and provided to SGC which tends to incorporated the full population range in the geological domains and a constrained population range in the grade domains in=line with the grade domain constraints.

- No assumptions were made by SGC regarding the recovery of by-products

- Copper, gold, molybdenum and sulphur were modelled as elements.

- Blocks in the model were defined based on the likely mining bench heights and the domaining took into account the SMU proposed at the outset of 4 m E by 4 m N by 2 m RL.

- The interpretation or domain model was largely driven by the lithology / geology, oxidation state, and structural intervention and mineralised trends observed over the various project areas. Grade was used as a secondary domain driver for the definition of boundarieswhere deemed appropriate by the XAM resource team.

- The model was validated in a third party software using section and plan comparisons back to original informing data as well as with the use of swath plots to assess local grade variability between the model and informing data.

|

| Moisture | - Tonnages are estimated on a dry basis.

|

| Cut-off parameters | - Mineralised domain interpreted on grade ≥ 0.1% CuEqRec inside the local interpretation solids by area with reference to local variability.

- Assumed to be reasonable cut-off for open pit and underground propositions given probability plot curve inflexions and grade population distributions.

- Resources estimated at a range of cut-offs and reported at a 0.2% CuEqRec cut-off grade for open pit and 0.3% CuEqRec for underground public reporting.

|

| Mining factors or assumptions | - This item is beyond the scope of work for SGC as such this item details were not addressed by SGC but will remain the responsibility of the Client and Client’s representatives.

- Consideration was given by SGC to SMU factors, blocks in the model were defined based on the likely mining bench heights and the domaining took into account the SMU proposed at the outset of 4 m E by 4 m N by 2 m RL.

|

| Metallurgical factors or assumptions | - No metallurgical factors or assumptions used to restrict or modify the resource estimation were employed by SGC proceeding or during the construction of the model. Metallurgical recovery was not modelled as an attribute of the model. To date preliminary historical metallurgical recovery analysis has indicated recovery of Cu% to be 90% and Aug/t to be 78% overall.

- To the best of SGC’s knowledge no further work has been conducted in regard to metallurgical recovery which would indicated anything to the contrary of the recovery numbers put forth by the Client.

|

| Environmental factors or assumptions | - No environmental factors or assumptions were used to restrict or modify the resource estimation.

|

| Bulk density | - Bulk density was estimated into block models and post processed on the basis of data analysis by primary domain and oxidation to assign missing values with average density values.

- In all 54,364 bulk density measurements were taken from non-specified drilling samples by XAM site representatives during the period 2014 through to 2023 drilling program. The remainder of the SG database is historical in nature.

|

| Classification | - The resource classification was based on drilling density (and the availability of data to present to the search neighbourhood, geological modelling, oxidation and, density and recovery data as well as data quality considerations

- The classification criteria is deemed appropriate by SGC.

|

| Audits or reviews | - Other than those noted in this report, to the best of SGC knowledge, no additional public and formalised audits or reviews have been undertaken to date concerning the Mineral Resource Estimates for Kharmagtai.

|

| Discussion of relative accuracy/confidence | - Outlines of resource classifications were reviewed against drill-hole data density and assays results and each block in the model has a resource classification which indicates the relative (block to block) confidence level.

- Mineral resource estimate technique was deemed appropriate by an internal peer review by SGC as were the estimates themselves.

- Total mineral resource estimate based on global estimate.

- No production data was available at the time the estimates were undertaken.

- The block model was produced to represent global estimates, however the model honours the local grade distributions appropriately given the drilling data provided and the domaining strategy employed.

- The relative accuracy of the Mineral Resource estimate is reflected in the reporting of the Mineral Resource as per the guidelines of the 2012 JORC Code.

|

JORC TABLE 1 - SECTION 4 - ESTIMATION AND REPORTING OF ORE RESERVES

Ore Reserves are not reported so Section 4 is not applicable to this Announcement.

Photos accompanying this announcement are available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/74a9929d-aa56-41a7-9485-78ce2c9d267b

https://www.globenewswire.com/NewsRoom/AttachmentNg/2eea4a23-bf41-4a3f-b1cb-09733767a0cb

https://www.globenewswire.com/NewsRoom/AttachmentNg/195841f8-35a7-4658-81a7-0398ff0646b5

https://www.globenewswire.com/NewsRoom/AttachmentNg/354406c4-d9d3-499f-848b-2a74b682043c

https://www.globenewswire.com/NewsRoom/AttachmentNg/a4d88903-f184-4a84-9a29-3097187927ad

https://www.globenewswire.com/NewsRoom/AttachmentNg/fafcc17d-63cf-434e-a2c2-60da00e5142c

1 ASX/TSX Announcement 8 December 2023 – Kharmagtai Mineral Resource grows by 13% CuEq; including >25% increase in higher-grade core

2 ASX/TSX Announcement 8 December 2023 – Kharmagtai Mineral Resource grows by 13% CuEq; including >25% increase in higher-grade core

Figure 1

Resource growth in CuEq tonnes between 2023 and 2024 MRE’s. Growth attributable to additional drilling is a comparison of the 2023 and 2024 MRE’s reported using the same 2023 reporting criteria.

Figure 2

Plan view of the Kharmagtai district showing the additional drilling informing the 2024 MRE update.

Figure 3

Cross section through the White Hill Deposit showing resource growth and open nature of the White Hill deposit with grades generally increasing with depth. Faulting has shifted the resource towards the surface in the south, suggesting additional drilling may add significant shallower tonnes and change the shape of the current pits.

Figure 4

Schematic Cross Sections showing the cut-off grade reporting boundaries at White Hill. The 2023 December estimate was reported using a simplistic RL depth for open pit potential based on work conducted during the 2021 Scoping Study. The 2024 resource is being reported using optimised pit shapes generated during the ongoing PFS.

Figure 5

Illustration of resource classification within the 2024 PFS pit shells.

Robert Spiers, Bsc Hons, MAIG

Dated the 21st day of August 2024

© 2026 Canjex Publishing Ltd. All rights reserved.